What quality management measures can be implemented during the injection molding process to ensure product consistency and reliability?

Title: Quality Management Measures in Injection Molding to Ensure Product Consistency and Reliability

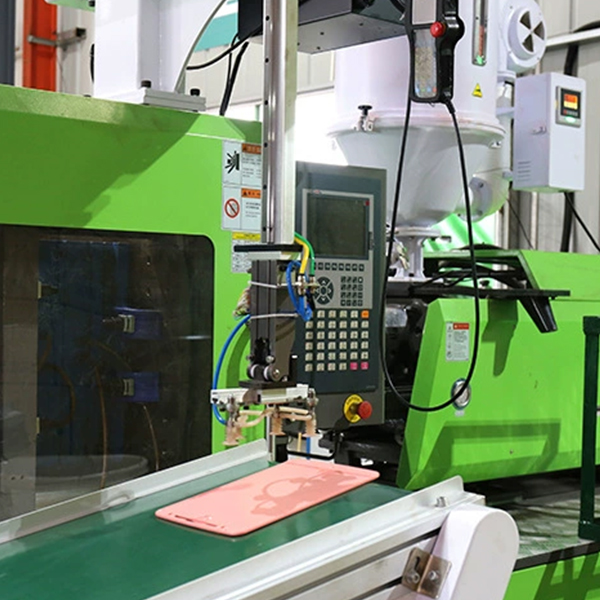

Abstract: Ensuring product consistency and reliability in injection molding is a multifaceted endeavor that integrates quality control measures throughout the entire process, from material preparation to final part inspection. Key practices involve precise process control, rigorous monitoring, and the application of advanced technologies to detect and rectify inconsistencies. This article highlights essential quality management measures to guarantee high-quality outputs in injection molding production.

Article:

Quality management in injection molding plays a pivotal role in delivering products with consistent dimensional accuracy, appearance, and mechanical properties. To attain this level of reliability, several interrelated strategies can be implemented:

-

Material Control: Ensuring the quality of raw materials is the first line of defense. This involves verifying the purity, composition, and moisture content of the resin pellets, as well as proper storage and handling to prevent contamination or degradation. Batch-to-batch consistency checks are crucial.

-

Process Parameter Optimization: Accurate calibration and adjustment of process parameters such as injection speed, pressure, temperature, and holding pressure/time are essential. Using scientific molding techniques and computer-aided process simulation tools helps establish optimal settings for consistent part performance.

-

Advanced Process Monitoring: Real-time monitoring of process variables like cavity pressure, mold temperature, and melt flow rate can alert operators to deviations from standard conditions. Integrated sensors and process control systems can automatically correct process fluctuations, enhancing part repeatability.

-

Mold Maintenance and Calibration: Regular mold inspections, cleaning, and maintenance ensure that the mold remains in top condition, minimizing flash, short shots, and other defects. Periodic mold alignment and calibration checks are also vital to uphold precision and uniformity.

-

In-Process Quality Checks: Inline inspection using vision systems, laser scanning, or coordinate measuring machines can detect dimensional variations and cosmetic defects immediately after molding. Catching issues early prevents defective parts from reaching downstream processes.

-

Statistical Process Control (SPC): Implementing SPC charts to monitor key process indicators can reveal trends and patterns that might otherwise go unnoticed. This statistical methodology enables proactive intervention to maintain process stability and control.

-

Documented Work Instructions and Standard Operating Procedures (SOPs): Comprehensive and updated work instructions coupled with SOPs provide clear guidelines for employees to follow, ensuring consistency in operator actions and decision-making across shifts.

-

Certification and Auditing: Adherence to industry standards, such as ISO 9001 or specific automotive or medical device standards, demonstrates commitment to quality. Internal and external audits reinforce compliance and drive continuous improvement efforts.

-

Employee Training and Certification: Ongoing training programs for staff members ensure that they have the necessary knowledge and skills to recognize and address quality issues. Certified personnel can manage complex processes more effectively, reducing errors and inefficiencies.

-

Root Cause Analysis and Corrective Action Plans: When defects occur, root cause analysis (RCA) should be conducted promptly. Implementing corrective and preventive action (CAPA) plans based on RCA findings helps prevent recurrence and further enhances process reliability.

In summary, implementing a robust quality management system in injection molding requires a combination of equipment precision, material quality control, advanced process monitoring, and a culture of continuous improvement. By integrating these measures into daily operations, manufacturers can assure customers of reliable, high-quality products consistently produced via injection molding processes.

Keywords: Injection Molding, Quality Management, Product Consistency, Process Control, Material Control, Process Monitoring, Mold Maintenance, Statistical Process Control (SPC), Employee Training, Root Cause Analysis, Corrective Action Plans.

Corporate Information

About Us

Alibaba Recommended Learning Products for Kids

Hi dear.

Welcome to our website.

This is Dongguan Aopu industrial Co.,Ltd was established in 2013 and is located in Dongguan city,China. Guangdong province,We are a professional manufacturer of electronic and 3C products, children's learning products, injection moulding and mould development. The main products are: electronic 3c products, children's learning LCD handwriting board, early learning card machine, mathematical oral calculation treasure, children's learning products, plastic products injection molding processing, parking equipment products so on.All products can be customized according to customer requirement. ODM/OEM are welcome.

Corporate Mission

We provided high quality products.Fast production time and best after-sale service.

Corporate Vision

Most of them are exported to regions and countries such as America, Europe, Canada, Australia, Japan, and so on. At the same time, manufacture and servings are outspread to South Asia, Africa and South America.

Contact Us

Recent Articles

Andy

Phone:+86 13713388773

E-mail:Andy@dgaopu.com