Recycling and Utilization of Injection Molding Waste in the Plastic Injection Industry

Title: Recycling and Utilization of Injection Molding Waste in the Plastic Injection Industry

Abstract: This article explores the methods and significance of recycling and utilizing injection molding waste in the plastic injection industry. It discusses the economic benefits and environmental significance of such practices, highlighting the importance of sustainable waste management. Keywords: injection molding waste, recycling, utilization, economic benefits, environmental significance.

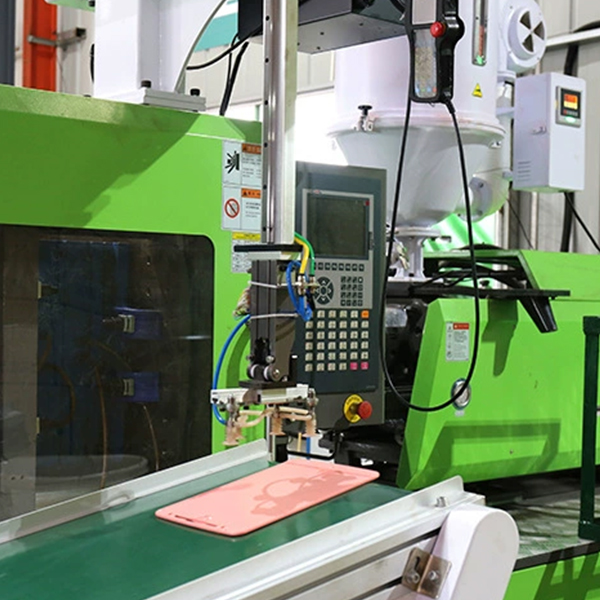

Introduction: The plastic injection industry is a significant contributor to global plastic waste generation. In recent years, there has been a growing emphasis on sustainable waste management practices, including the recycling and utilization of injection molding waste. This article aims to discuss the methodologies employed and the economic and environmental advantages associated with these practices.

Methods of Recycling and Utilization:

-

Sorting and segregation: Injection molding waste, such as sprues, runners, and rejected parts, first undergoes sorting and segregation based on material type. This enables efficient recycling processes.

-

Reprocessing: The sorted waste is then subjected to mechanical or chemical processes to transform it into reusable raw materials. This can involve processes such as shredding, melting, and pelletizing.

-

Integration into production: The recycled materials are reintegrated into the manufacturing process, either as raw materials for new products or as additives for improving material properties. This significantly reduces the reliance on virgin plastics.

Economic Benefits:

-

Cost savings: Utilizing recycled injection molding waste reduces the need for purchasing virgin plastics, resulting in cost savings for manufacturers. Additionally, the cost of waste disposal is minimized through recycling practices.

-

Revenue generation: Some companies specialize in the collection and processing of injection molding waste, providing a potential revenue stream through the sale of recycled materials.

Environmental Significance:

-

Resource conservation: By recycling and reusing injection molding waste, there is a reduced demand for new plastic production, thereby conserving valuable natural resources like crude oil.

-

Energy savings: The production of plastics from recycled materials requires less energy compared to the production of virgin plastics. This leads to reduced greenhouse gas emissions and a smaller carbon footprint.

-

Waste reduction: Proper management of injection molding waste through recycling and utilization helps minimize landfill space and reduces the environmental impact associated with plastic waste disposal.

Conclusion: Recycling and utilizing injection molding waste in the plastic injection industry offer significant economic benefits and contribute to a more sustainable and environmentally friendly manufacturing process. By implementing these practices, manufacturers can reduce costs, conserve resources, and mitigate the environmental impact of plastic waste. It is crucial for the industry to embrace these methods and foster a circular economy mindset for a greener future.

Keywords: injection molding waste, recycling, utilization, economic benefits, environmental significance.