Evaluating and Selecting Injection Molding Machines for Large-Scale Production

Title: Evaluating and Selecting Injection Molding Machines for Large-Scale Production

Article:

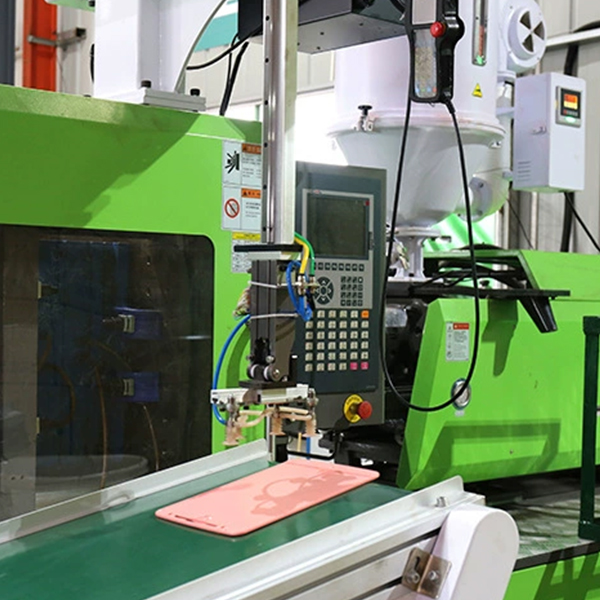

Large-scale injection molding operations demand machines that are not only robust and efficient but also adaptable to varying production needs. Selecting the right injection molding machine for high-volume manufacturing involves a meticulous evaluation of several key factors:

-

Clamping Force: The clamping force determines the machine's capacity to hold the mold shut against the pressure generated during injection. It is essential to calculate the required clamping force based on the projected part's surface area and the expected injection pressure to ensure sufficient mold closure.

-

Shot Capacity and Injection Volume: Evaluate the machine's shot capacity and injection volume to match the size and weight of the parts you plan to manufacture. A machine with a larger shot capacity than necessary can lead to wasted material, while one that is too small will limit production capabilities.

-

Screw Diameter and Injection Pressure: The screw diameter influences the amount of plastic that can be processed and the injection pressure. A larger screw diameter is suited for higher volume production and thicker parts, while higher injection pressures are required for materials with high viscosity or intricate mold geometries.

-

Machine Size and Footprint: Consider the available floor space in your facility when selecting a machine. Large-scale production often necessitates machines with greater dimensions, but optimizing layout and choosing machines with compact designs can help maximize space efficiency.

-

Energy Efficiency: Energy consumption is a significant cost factor in large-scale production. Look for machines with energy-saving features like variable displacement pumps, efficient heating and cooling systems, and idle mode functions to reduce operational costs over time.

-

Automation and Integration Capabilities: Automated features such as robotic arm integration, conveyors, and part handling systems can significantly boost productivity in large-scale operations. Machines with Industry 4.0 compatibility, such as IoT connectivity, enable real-time monitoring and data analysis for process optimization.

-

Machine Speed and Cycle Time: Fast cycle times are crucial for maximizing output in high-volume production. Assess the machine's injection speed, cooling efficiency, and ejection systems to ensure they align with your production targets.

-

Flexibility and Compatibility: Choose machines that can handle a variety of materials and part sizes to accommodate future production changes. Machines with interchangeable molds and adaptable process controls offer greater flexibility for diverse manufacturing demands.

-

Supplier Support and Service: Strong after-sales support, technical assistance, and readily available spare parts are vital for maintaining uptime in large-scale production environments. Evaluate suppliers based on their service networks, warranty offerings, and responsiveness.

-

Cost-Benefit Analysis: Conduct a comprehensive cost-benefit analysis considering the initial investment, operating costs, maintenance expenses, and potential return on investment. Factor in scalability and future-proofing to ensure the machine's long-term suitability.

Abstract: Selecting injection molding machines for large-scale production involves a comprehensive evaluation of technical specifications, energy efficiency, automation capabilities, and supplier reliability. By carefully assessing clamping force, shot capacity, screw diameter, machine size, energy consumption, automation compatibility, cycle times, flexibility, and overall cost-effectiveness, manufacturers can ensure that their choice supports high-volume production demands while maintaining efficiency and profitability.

Keywords: Injection Molding Machines, Large-Scale Production, Clamping Force, Shot Capacity, Screw Diameter, Energy Efficiency, Automation, Cycle Time, Flexibility, Supplier Support, Cost-Benefit Analysis.